Building a 3D printed race car

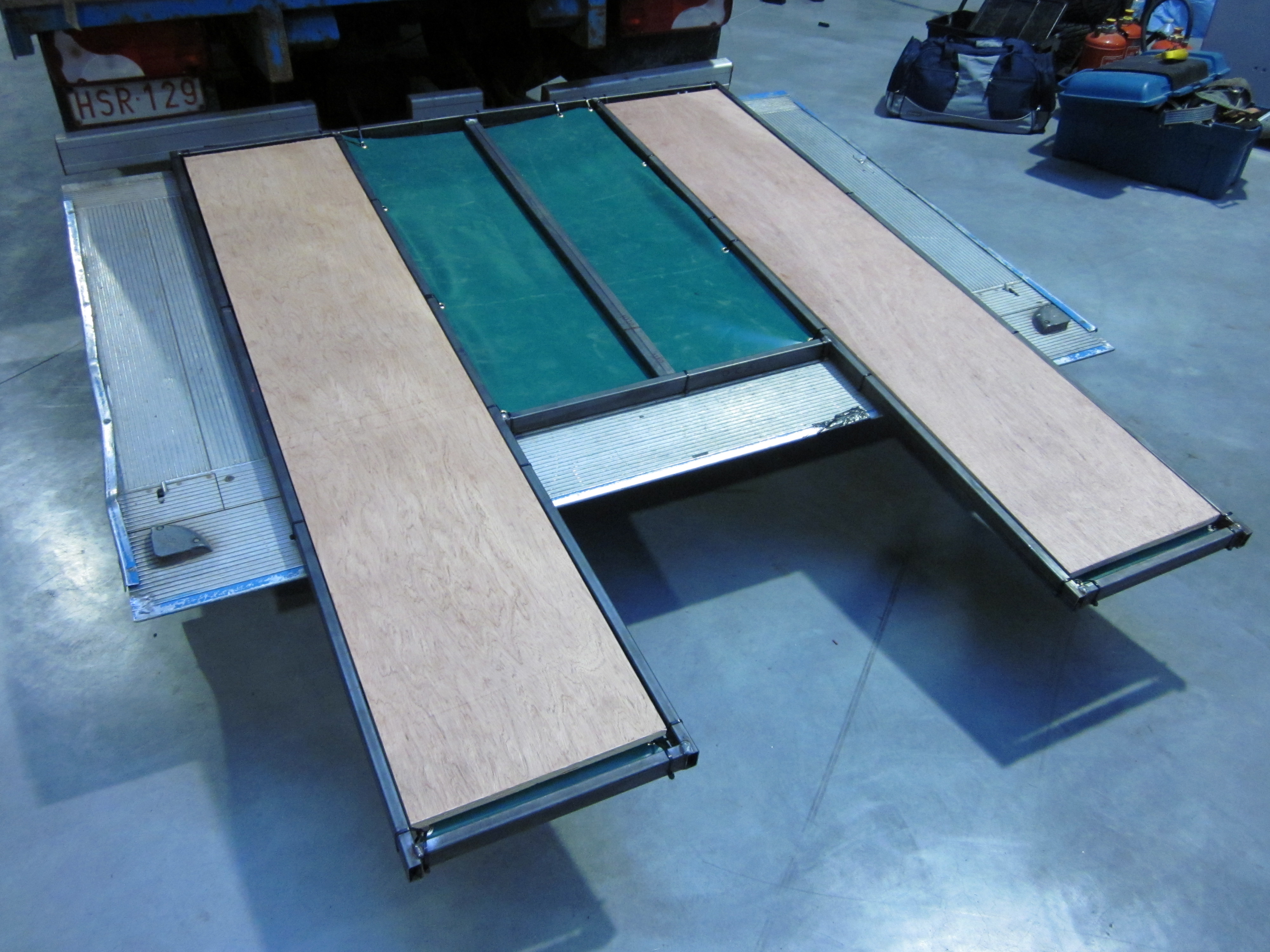

After my freshman year of college, I was hired by IMEC, an international research company to work in Belgium for the summer. I had no idea what awaited me there, but it was fantastic. Given my experience with fabrication, I was assigned to work with Formula Group T, working on their first entry in the European Formula Student competitions - Aerion. Not only did I sharpen my welding and manufacturing skills, I worked with cutting edge technologies like biodegradable composites, laser sintered titanium, and 3D printed body panels that were nearly 2 meters long. I designed and fabricated a shipping container for the car to protect it en route to England and Germany, as well as advising in the manufacture and assembly of the vehicle. The shipping container design was such that the lid doubled as an on-ramp for the vehicle so that it could be driven on and off the truck. Additionally, the entire assembly could be unbolted and stored up against a wall in a space no wider than 10 cm. I was so fortunate to have the opportunity to travel abroad, learn so much about Belgian culture, and be part of building a high powered, all-electric, racing machine.