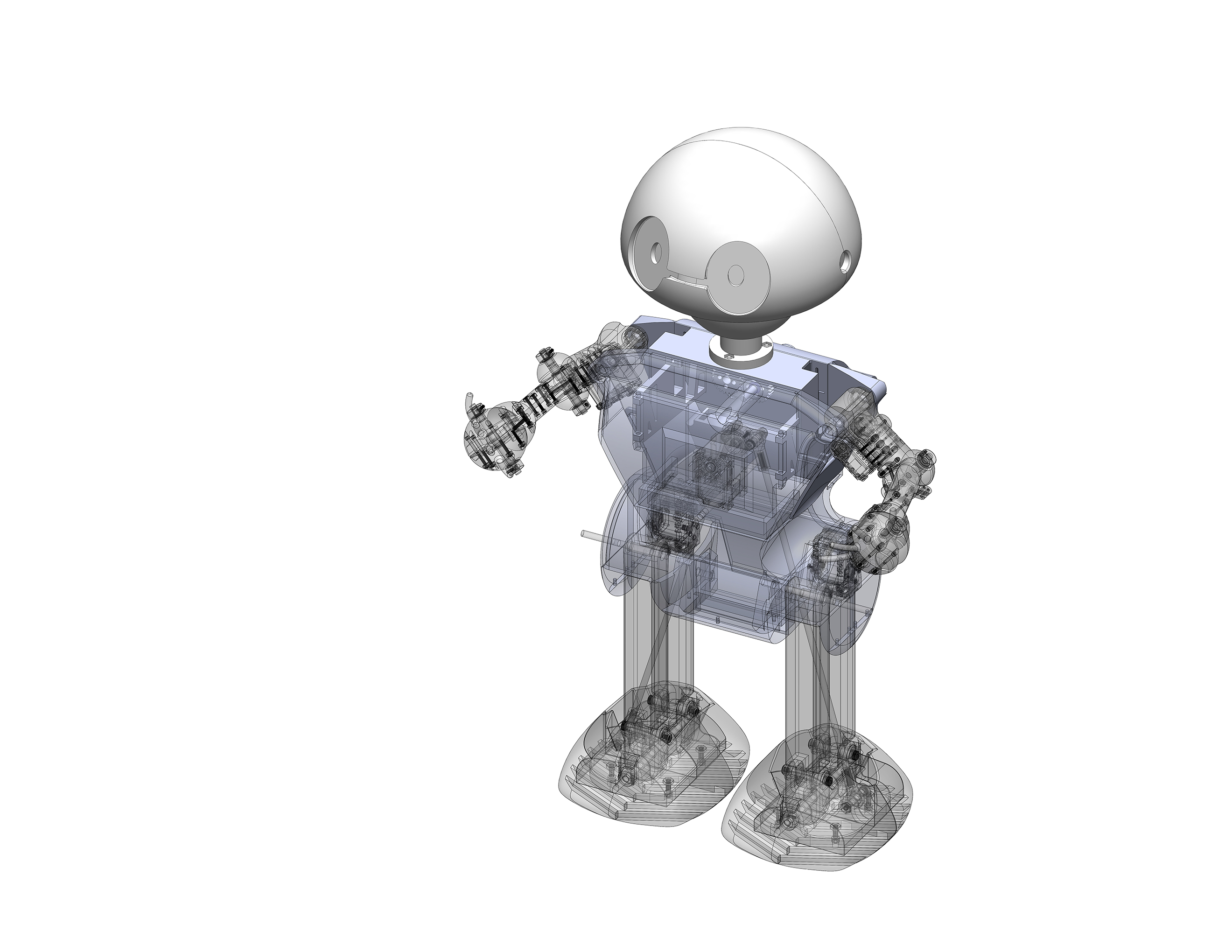

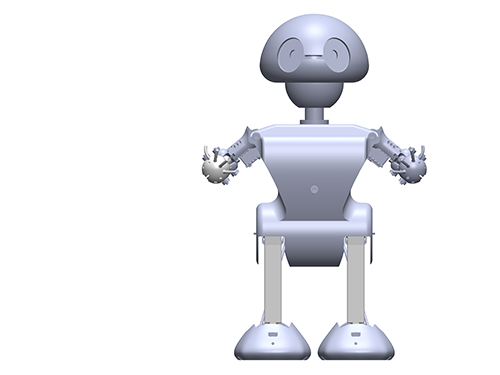

JIMMY - Your 3D Printed Friend

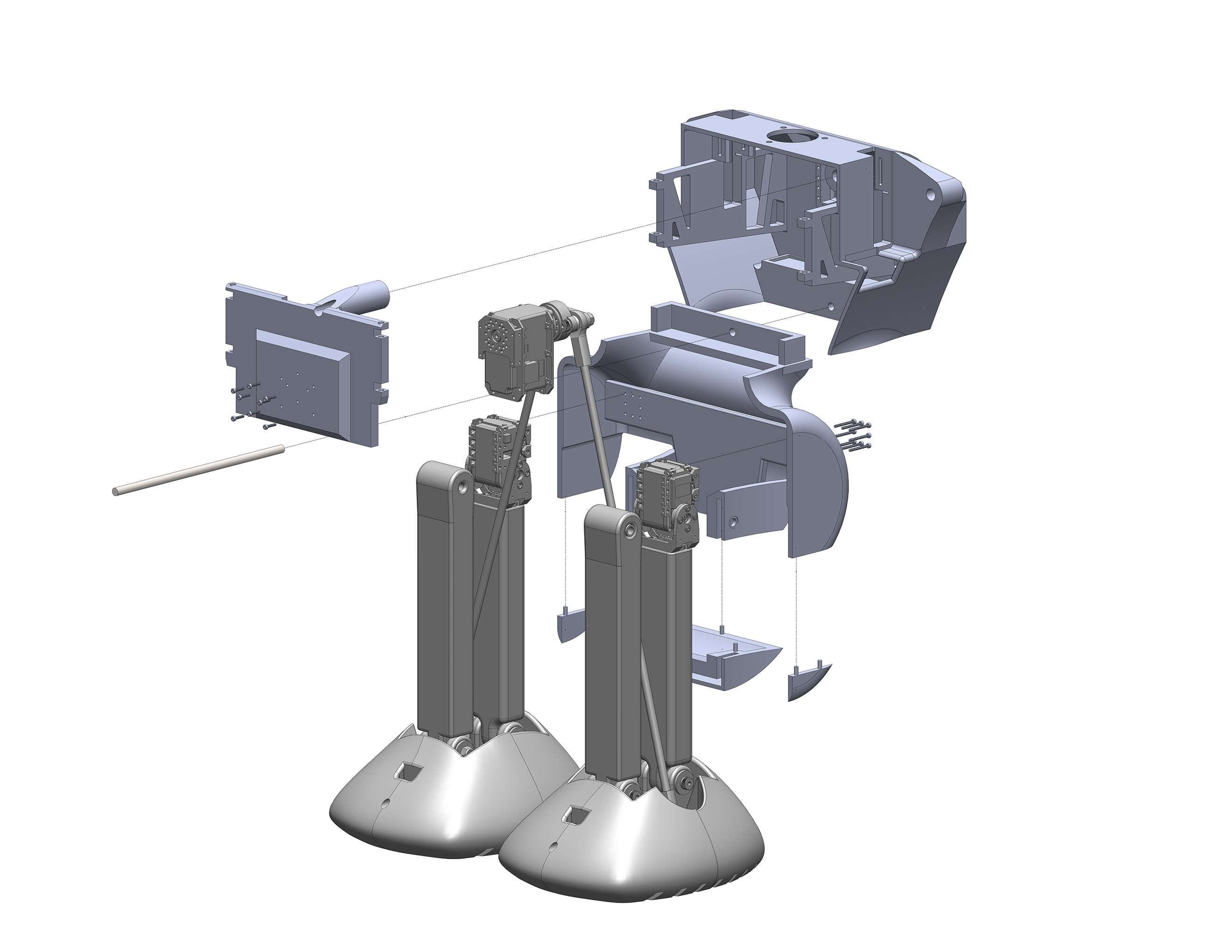

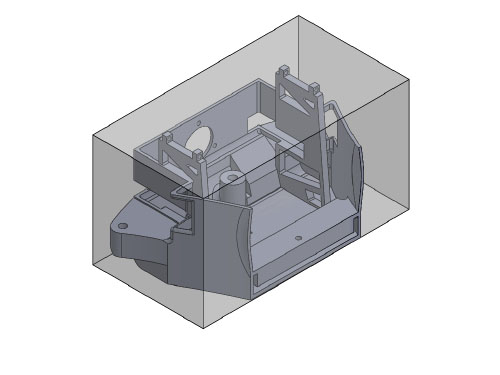

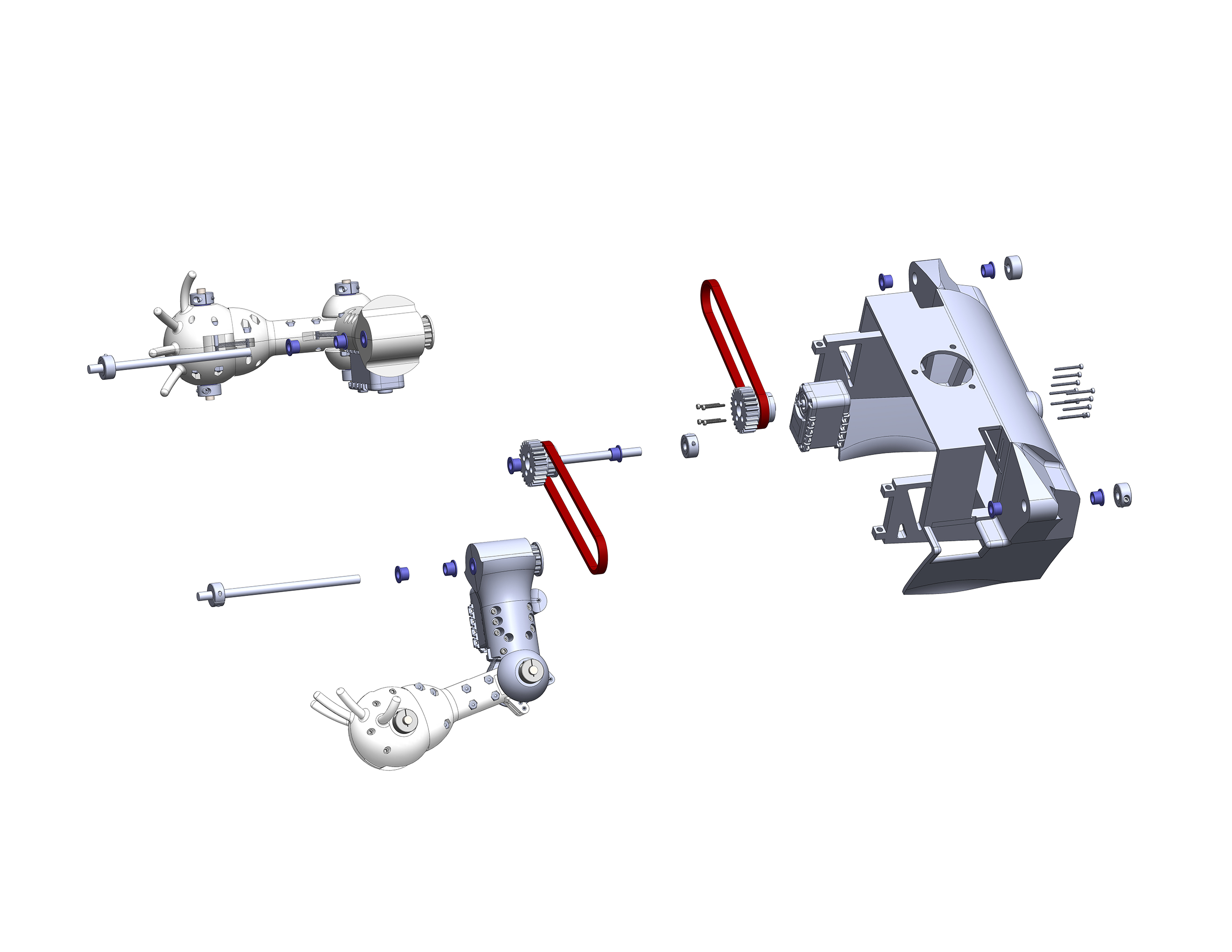

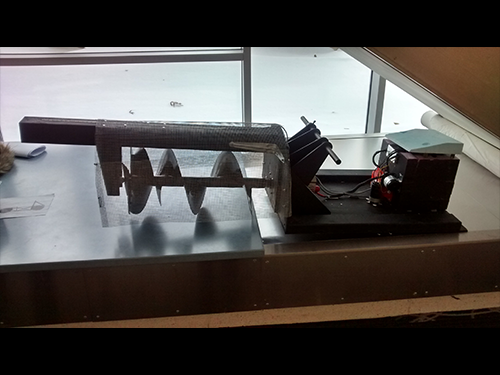

Intel approached our Mechanical Design class with an interesting proposition: design, and potentially build, a robot made from completely 3D printed parts. The intent of this project was to develop an affordable platform that would allow high school and college students the ability to use and interact bipedal robots in their studies and research, without requiring a massive budget. Intel provided the artistic inspiration, while our job was to design the linkages, drive mechanisms, and structures to make it happen. In addition, each team was assigned a target price point; for JIMMY-B this was roughly $1500 in parts, not counting shell material or electronics for controls. That limited articulation to only two or three servo motors for actuation. The design was challenging, and halfway through we restarted after reaching the conclusion that our original design would not work. Our team buckled down and worked like mad, finally developing a design we felt confident could be built and still meet the price target. From this experience I gained a lot more experience in working with a large design team, getting creative with fasteners, and thinking through the user experience when assembling the robot.